Introduction

The pace of the warehousing and logistics world comes with an unsung hero: the forklift. It has come to play a role in all operations dealing with mass movement from and to the warehouse, with speed and skill enough for extraordinary accuracy. But one area seldom given the importance it truly deserves pertains to the lights that are such a critical part of safety and productivity. As we try to walk through the milestones of material handling, one among these is the evolution of lighting for the forklifts. From basic incandescent bulbs to the sophisticated LED systems of today, lighting solutions have undergone a transformative journey paralleling so many technological advancements.

Definitely, the advent of LED (Light Emitting Diode) technology emerged as an altogether new call-in for forklift lighting that brings on board a host of benefits in comparison to the earlier ones. Widely used for their extreme efficiency performance, robustness, and incredible life, LED lights have come to re-echo safety and operational standards in any warehouse. Nowhere else is this principle more firmly established than in the forklift industry, with the introduction of innovations—one foremost: the LED Forklift Three Color Rear Tail Light. That outlines the evolution and innovative functionalities of the LED Three Color Rear Tail Light and enhancements in safety standards and extrapolates broader implications upon operations in the warehouse with utmost accuracy and vividness on how LED lights are transforming forklift operations.

The Evolution of Forklift Lighting

All aspects of forklift operations showed the technology story of industrial equipment. Forklift lighting in the past was characterized by the presence of rudimentary incandescent bulbs. They were not at all efficient, nor very robust, with bad quality light. Quite often, they had a short life due to the very hard impacts applied to them under construction sites, vehicles, and warehouses. The photons emitted were of lower energy and could, therefore, because visibility problems, especially in environments highly clustered with light and obstacles.

After that, an improvement in lighting solutions followed when industrial needs continued growing. Halogen lights briefly became the standard and offered a more radiant source of light with a longer lifespan than their incandescent precursors. However, it was still facing a myriad of critical issues, including high energy consumption and heat production, which made it less ideal for continuous illumination in forklift operations.

Really, this came as a breakthrough with the coming of the Light Emitting Diode (LED) technology. LEDs are small, consume little energy, and make it possible to achieve an extremely long forklift service life. Unlike them, LEDs are solid-state lights and do not produce light through glass capsules that may be affected in case one is working in vibratory conditions, which is typical for forklift usage. In addition to this, they offer instantaneous lighting without any warm-up and allow both increased brightness and color temperature for better vision under different work conditions.

Today, LED lighting is not only a technical possibility but also a standard in modern forklift design, the benefits of this product being irrefutable in terms of operational efficiency, safety, and maintenance costs. This technological leap is best illustrated by the LED Forklift Three-Color Rear Tail Light that amalgamates several signals together into one ruggedly constructed, power-saving unit.

Features of the LED Forklift Three-Color Rear Tail Light

Our new lighting solution combines three features of turn signals, brake lights, and reverse lights into one unit. It is an innovative yet compact and toughly built unit engineered specifically for heavy usage in applications that involve forklifts. The following are the product attributes of the Three Color Rear Tail Light:

1.Versatile: The brake, turn, and reverse use red, amber, and white LEDs. Thereby, it adds simplicity by reducing the number of separate lights to be installed at the rear end.

2.Durable: Sealed in an aluminum casing, the LED light is designed to guarantee the longest life possible under some of the harshest industrial conditions, from dust and other debris to extreme vibrations and shocks.

3.Energy-Efficient: LEDs have been proven to be very energy-efficient, and this is definitely a feature linked with this tail light. It provides a bright, clear signal with the least use of energy, so it adds up to the efficiency of the truck in totality.

4.Lasting: LED lights have more long-lasting qualities than any other traditional lighting option found on the market, curbing replacements of the Three Color Rear Tail Light to a lesser extent in maintenance time and cost.

5.Compatibility: It is designed to fit universally in a wide range of forklift models, including Toyota 7FD, without being left behind by Clark and Hyster models.

The section here below provides some general insight into safety improvements or benefits that arise when carrying out the implementation of this LED light solution into the operation.

Advantages

This pivotal and colossal move in the direction of road safety has successfully been assimilated into the working pattern of the LED forklift rear tail light for Forklifts. Some key benefits are basically consistent throughout.

Brighter Light: The LED lights used are designed to have better illuminating features than the old conventional lighting; hence, the signals from the forklift are well visible even under bright lighting indoors or outside.

Distinct Color Signals: These three simple colors (brake-red, turn-amber, and reverse-white) are bright and easy to see. They clearly communicate the signals, helping to avoid any misunderstandings and accidents with surrounding staff or other forklift drivers.

Instant On/Off: Unlike an incandescent bulb, which may need a moment to achieve its maximum brightness, LEDs light up at full capacity in an instant. This means workers are being provided with extra moments that can help them react better to the movements of the forklift and, hence, improve safety even further.

Longer Life: As a solid-state device, LEDs are less prone to damage, unlike what happens so often with the rough and tumble these bulbs endure, for example, in warehouses and distribution centers.

Longevity: LED lights last for several thousand hours longer than incandescent or fluorescent bulbs, resulting in the replacement of light bulbs relatively much less frequently. Therefore, LED lights reduce maintenance downtime and all associated costs.

Lower Power Usage: Uses less power, thereby consuming less energy. In addition, the less load exerted on the forklift’s electrical system may save money by extending the life of the battery and the time between charges.

Impact on the Environment: It is eco-friendly because LEDs are free from hazardous substances that are present in other conventional bulbs and have a longer life.

Installation

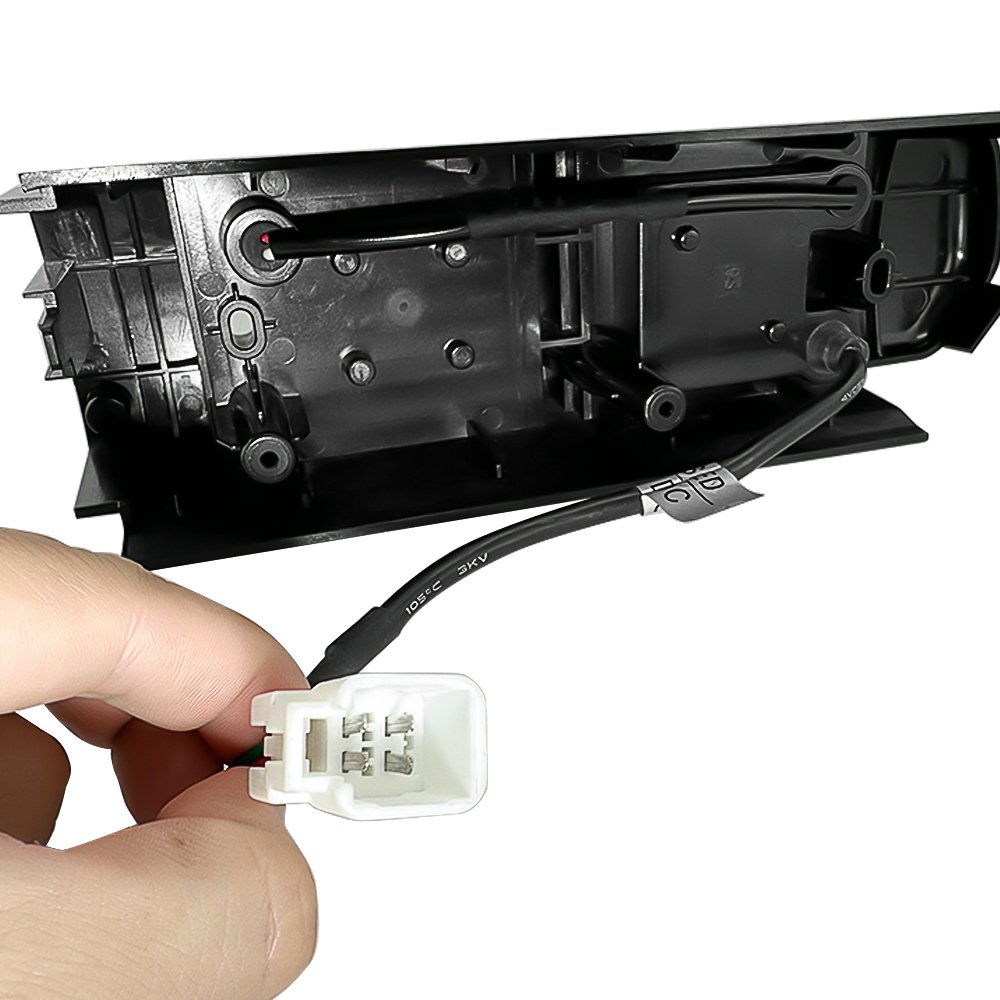

Its minimalistic design makes the LED Forklift Three Color Rear Tail Light easy to install, so any vehicle warehouse or logistic center can upgrade its forklifts within a short downtime period without sophisticated adjustments. In general, its plug-and-play installation ensures a user-friendly process even for those less experienced. These are not only compatible with so many forklift models but also add to the fact that the benefits of LED lighting can be universally added, and these safety and efficiency advantages can be realized in many warehouse operations. Moreover, we offer Wholesale Forklift Tricolor Rear Lights.

The implication of Safety, Efficiency, and Sustainability

Several implications are brought about by the adaptation to the LED Forklift Three Color Rear Tail Light solutions in various warehouse operations in terms of safety, efficiency, and sustainability. With modern light systems comes better visibility and clear communication, thus reducing one’s exposure to danger and consequently offering a safer working environment to the staff. The unmistakable clarity of LED signals designed in distinct colors for operational differences can pave the way for an excellent safety protocol in any busy warehouse setting.

In combination with security facilities, the energy-efficient strengths and long lifecycles of LED lights help provide significant reductions to operational costs. Warehouses are set to make great savings on energy and maintenance because of LED lights, which consume very little power and have a much longer life compared to other types of lighting options. It does this by ultimately increasing the operational time of the forklift trucks while also maximizing uptime so that business flows are continuous and smooth.

It is considered that in the face of changing trends across the globe, they are embracing change toward sustainability. In so doing, the adoption of LED lights has been revolutionary, given the demanding environment in which warehouses operate. This is indeed true not only for the LED lighting alone but also for the LED Forklift 3 Color Rear Tail Light itself as, besides being environmentally friendly, it is also free from hazardous materials. This makes LEDs a safer choice, not only for the workplace but also for the environment.

Not only this, but the environmental benefits realized from changing to LED lighting are wonderful as it helps to create a more environmentally friendly. It is non-hazardous nature. The kind of change being planned for is not just beneficial for the overall sustainability of the planet but also meets the growing market requirement towards awareness.

It remains a major technology in reducing carbon emissions, one of the critical issues of climate. There would be ever-bigger global reasoning towards less energy consumption with LED lighting of warehouses as these go parallel to efforts that aim to have the least impact on the environment. All these efforts in sustainability are clearly a brand enhancement tool, mostly and especially targeting eco-conscious customers and stakeholders.

This integration fundamentally redefines the nature of warehousing environments as it absolutely cultivates a culture of safety and represents contemporary modern warehouses’ operational standards and efficiencies that are green and sustainable. As these technologies become pervasive, so does the very future of how logistics and material handling can be made safer, cheaper, and greener.

Future Outlook: The Role of LED Lighting in Smart Warehouses

In the future, LED lighting will become more advanced with the burgeoning developments of smart warehouse technologies, such as IoT. Such a solution, being smart, flexible, and controllable, will likely be an active participant in the ecosystem of the smart warehouse. The very fact that these days, LEDs can be integrated with sensors and other devices dealing with IoT (Internet of Things) creates new opportunities for optimization for many people dealing with warehouses. For example, smart LED systems reduce energy consumption and decrease costs even more through the use of lighting that is adapted to natural light conditions and whether or not workers are present.

Data collected from smart LED systems may also potentially provide means for real-time predictive maintenance and optimization of warehouse operations. This control and intelligence aspect adds not only to full operational efficiency but also quality levels of safety and convenience amongst the warehouse staff.

Conclusion

At its core, the LED Forklift Three Color Rear Tail Light stands for an actual paradigm shift in striving to make warehouses safer and more productive. They will indicate the path to be followed; they are the guides of safety, clarity, and operational excellence in the maelstrom of activity in our warehouse corridors. Our custom turn, brake, and reverse signal combination in one reinforced unit make work simple while drastically improving the ability of lift truck operators to safely and efficiently communicate with ground personnel. The gains actually go much further than just these alone, creating an environment that speaks of more safety and productivity reverberating through every aisle and loading bay.

Go ahead and do it now. Brighten up your forklifts with the new Forklift Tricolor Rear Light and make your operations take notice of safety and make them futuristic like some others that put their team’s welfare on the list of priorities while ensuring operation runs smoothly. Don’t wait for the next incident in safety or a productivity hitch to come driving change. Make a proactive step toward a better, safer, and more efficient tomorrow. Contact us (Forklift Tricolor Rear Light Suppliers) now to explore how our LED solutions can transform your warehouse operations.